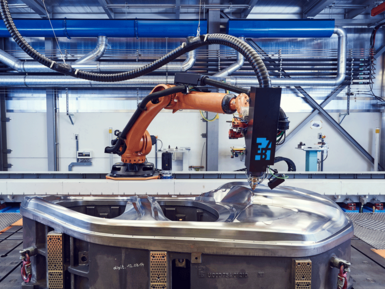

The SynchroSpot 400 sees the development and construction by EBZ of a unique special machine for introducing large molds with the highest levels of precision.

Innovations at EBZ

For us, research and development means investing in the future. This involves continuous improvement of existing products and services and the creation of innovations as important pillars of the success and dynamism of the EBZ Group. Customer benefit is at the heart of our development work and, in particular, regarding our ability to be a one-stop provider of tailored solutions. However, we are not exclusively customer driven during development of innovative products, improved services and more efficient processes, but primarily through our own motivation and conception of ourselves. The combination of customer-oriented development work and our own innovativeness ensures we are appreciated in competition between the best solutions in our existing segments and, also, in future as a reliable pioneer.

Our innovations at a glance

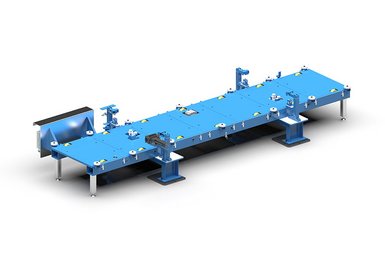

The conveyor system is distinguished by an extremely slim and low design height and the very short transportation duration from station to station.

The high-speed roller conveyor (HSR) is a transport and positioning system for geometry pallets as commonly used in body shop plants.

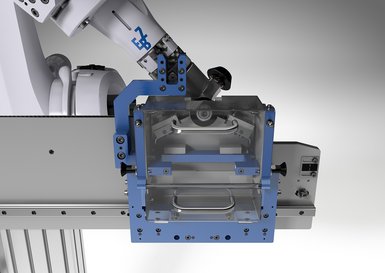

Hemming roller cleaning - automated and without cycle time loss

Much of the research and development work takes place in our Technology & Innovation Center (TIC) at the Ravensburg location. A dynamic and highly motivated team works continually here to implement the latest projects. Our comprehensive test center encompasses a test lab for electronics, the required robot and automation technology and a variety of test circuits. This center is a one-stop venue for everything from the original idea to its implementation, including mechanical design and its structure, e-design, electrical installation, software development and subsequent implementation for validation and optimization.

Performance is demonstrated in innovations in the area of materials handling such as our high-speed roller conveyor or the monotrack (low speed and high speed). The latest proof of performance is to be found in the design and development of probably the most accurate spotting press in the world, the SynchroSpot 400, for use in our own in-house toolmaking.

Please do not hesitate to contact us!

Your contact