Henrik König

Sales Management

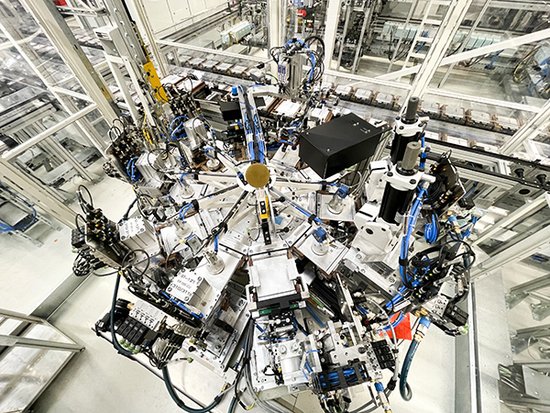

Technological change in the automotive drivetrain is already playing a significant role today. This will expand further in the coming years and become increasingly important.

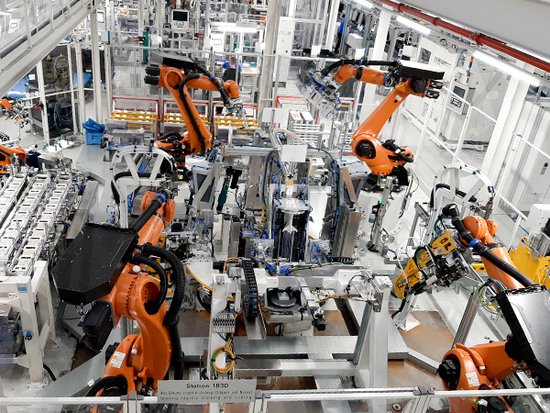

EBZ provides process-reliable, high-quality systems for the assembly of energy storage systems, adapting the level of automation, cycle times and output volumes to meet customer specifications.