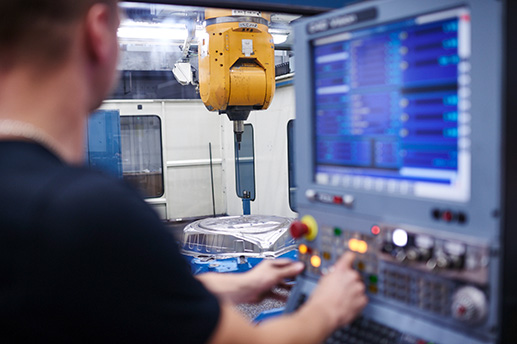

Precision contour grinding

Mechanical production

In terms of accuracy and productivity, our tools meet the highest series production requirements in the automotive industry.

This is backed by a state-of-the-art machinery inventory and highly experienced well-trained employees. More than 15 machining centers and our own hardening plant ensure precise and efficient production of tools and components.

Our manufacturing solutions and services:

- NC programming: CAM/WOB programming

- High-performance cutting (HPC roughing)

- High-speed cutting (HSC finishing)

- Workpiece sizes up to 12 m

- In-house heat treatment competency:

- Surface hardening through induction and laser technology

- Through hardening with a vacuum furnace - Multifunctional laser center (7 axes) with laser build-up welding, laser hardening and laser cutting

- Realization of individual production steps

Tool design and assembly

The assembly of complex tools demands maximum precision and many years of experience. We can offer you both. Our tool mechanics have the necessary know-how and craftsmanship for this task. They use the latest assembly methods and welding techniques, creating tools that are functionally exact in their structure and ready to use in our press plant.

Our tool assembly encompasses the following services and solutions:

- Tools of every complexity and size up to 5000 x 2800 mm

- Know-how: outer skin, aluminum, high-strength steels

- Detailed assembly sequence and subsequent processing planning to achieve maximum accuracy

- Precise configuration of the most intricate and complex interdependent kinematic functions

- Straking of HSC surfaces up to Class A quality including provision to the press plant

- Manufacture of individual, pre-fabricated tools