Toolmaking

Our toolmaking services

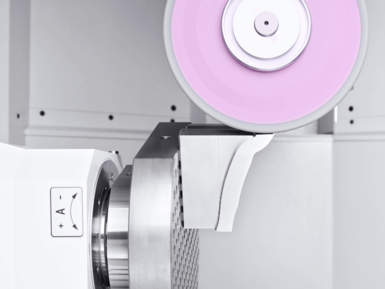

In terms of accuracy and productivity, our tools meet the highest series production requirements in the automotive industry.

We give the highest priority to component inspection. We employ the latest measurement technology to monitor and optimize all products and production processes.

of cutters and mold jaws in individual and small series production.

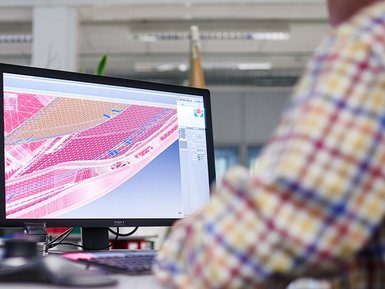

EBZ develops high-precision, efficient and reliable tools.

This requires the highest level of experience and technical design and production expertise. This is particularly the case during production of outer skin parts and complex structural components. Our engineering expertise merges with our skilled craftsmanship in the try-out.

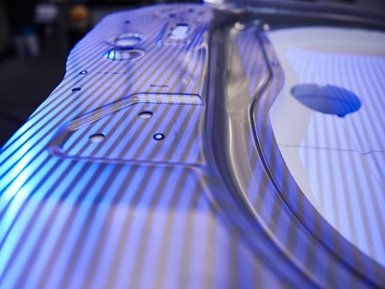

As a specialist in forming technology for customary deep drawing steels, aluminum, and CFRP / GFRP composites, our customers can rely on our extensive experience. Our goal is to offer the latest technology at the highest level of quality. For this reason, our global resources include state-of-the-art equipment for mechanical forming and assembly, measurement and quality assurance, and optical digitization. A laser technology center designed to address the particular needs of the company makes an important contribution to consistent and efficient work processes in sheet metal processing.

We map the entire toolmaking process chain, meeting the expectations of our customers right up to and including series production. We incorporate the tools in our own press line. This near-series try-out is equipped with the latest customer-specific press technology and can simulate incorporation prior to delivery. When the tools are integrated in presses for the first time at the customer’s premises, our high quality standards are demonstrated right down to the finest detail – from process-reliable design to efficient realization.