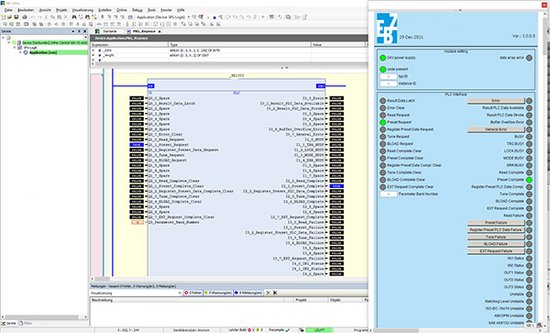

Virtual commissioning (VC)

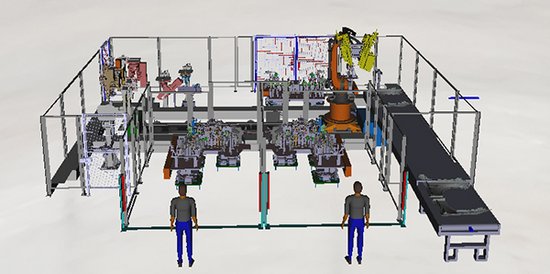

It is used for pre-testing of control software and robot programs in plant construction. The system is visualized in 3D with appropriate software and the behavior of the real system simulated. This means that systems can be secured, and their function tested prior to the actual commissioning. The EBZ Group has established an office for this purpose that is equipped with the latest simulation computers and a PLC control cabinet specially designed for this application.

Challenges of virtual commissioning

The greatest challenge is the realistic virtual image of the systems and their functions. Each electrically relevant component actuated by the PLC must be depicted in its function and behavior during virtual commissioning. This is achieved with the aid of behavior models. The EBZ virtual commissioning team is capable of creating its own behavior models and developing them for our customer library. These can then be used for further projects.

Benefits

The main focus in virtual commissioning is on quality enhancement and backing up PLC and robot programs. This allows us to detect errors in the control program and process at an early stage and remedy these before the real commissioning.

It also helps us with regard to the duration of the project, to shorten the time required for commissioning at the customer’s, and to enhance efficiency. Virtual commissioning is also an important tool for the EBZ Group with regard to our suppliers, as we can conduct a production status check of the software and robot programs in advance.

Services

Virtual commissioning allows us to run complex systems in advance and, consequently, meet the current expectations of our customers in terms of project duration and costs.

What advantages does virtual commissioning offer customers?

- Early detection and remedying of errors

- Early detection of risks

- Early testing of system functionality

At what time is this used?

Virtual commissioning occurs prior to real commissioning. At EBZ, >90% of our new systems and integrations undergo virtual commissioning.

Digital twin

The digital twin is an exact replica of the reality and an extension of virtual commissioning. An exact image of the real system is created from the virtual commissioning model, identical in appearance and behavior. This makes it possible to react speedily to changes in the software. These can then be tested on the digital twin and verified before being imported into the real system.

Challenges

The main challenges when creating a digital twin are playing back the real information and changes in virtual commissioning. The digital twin must be continuously updated and reflect the reality if one is to be able to return to virtual commissioning at any time. This is primarily the case in the area of behavior modeling and the 3D image. Virtual behavior models must behave like the real component. The 3D image must be an exact depiction of the real system if analyses are to be conducted and optimizations realized.

Benefits

The greatest benefit of a digital twin is that we have the possibility at any time to test and verify changes to the PLC and robot programs on the digital twin before these are imported into the real system. This saves us a lot of time in integration projects and conversions of systems in particular, since such changes can usually only take place on weekends.

Digital shadow

The digital shadow is also an extension of the virtual commissioning model. The focus during this is primarily on monitoring of the system. The 3D model is linked directly to the real system and transmits the plant status live. It is possible to monitor the system from a central position via a webstream, enabling targeted intervention in the event of faults. Specific system information can also be displayed in the digital shadow, with the worker receiving important information and operating instructions in the event of a malfunction.

Challenges

As with the digital twin, the challenge here is also to keep the 3D model updated. In addition, it is important to discuss in close cooperation with our customer which information should be imported into the digital shadow and how we can obtain this information.

Benefits

One of the greatest advantages of the digital shadow is the monitoring and analysis of systems from a central position. It is possible to move freely in the 3D model and examine special situations more closely without having to stop the real system. Faults which, for example, occur in the previous shift can be reproduced without difficulty in the digital shadow, analyzed, and remedied.

Your contact