Jonas Fimm

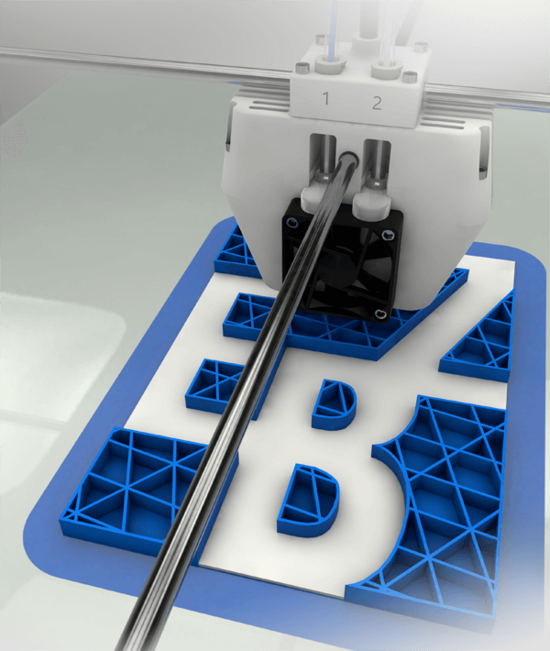

3D Printing

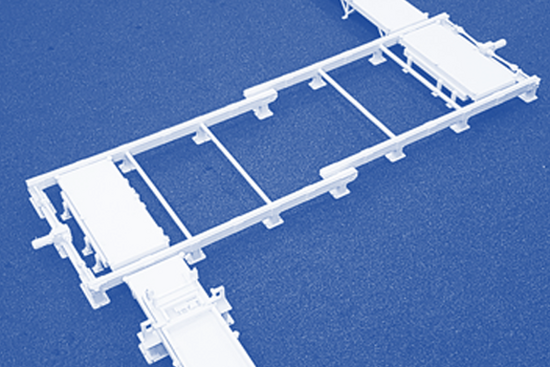

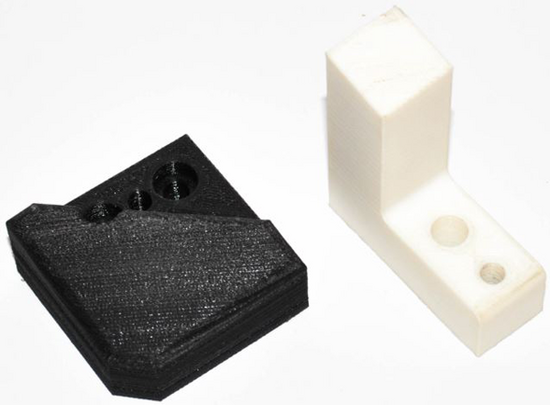

A variety of efficient solutions are achieved as a result, particularly in prototyping, production of individual parts and the manufacture of display models.

In addition to purely 3D printing, the EBZ Group also supplies the complete process chain in this respect, right up to testing at the customer’s premises.